Flow Meters

- Home

- Flow Meters

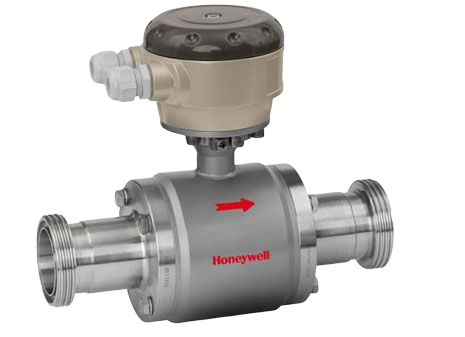

VersaFlow Clamp-on Ultrasonic Flow Meters

Honeywell’s VersaFlow Clamp-on Ultrasonic flow meters measure liquids in industrial applications. Because the sensor is clamped on to the outside of the pipe, it is immune to the process compatibility concerns of an in-line flow metering technology.

What Is It?

A market leading process measurement device, the VersaFlow Clamp-On Ultrasonic flow meters are designed for applications where a customer is unwilling or unable to cut into the process measurement line to install an in-line meter. Available in configurations for pipe line sizes from DN15 to DN4000 (1/2” to 160”), the clamp-on design offers a cost-effective means of measuring liquid flow through a pipe. With designs that can withstand up to 200˚C (392˚F), this technology is ideal for liquids with limited solids or gas content. Because it mounts on the outside of the pipe, there is no need to worry about material compatibility with the process being measured or the pressure in the pipeline.