Pressure Measurement

- Home

- Pressure Measurement

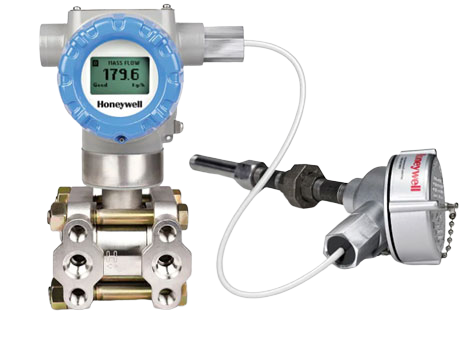

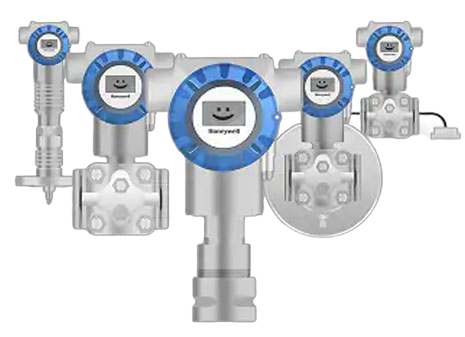

SmartLine Multivariable Transmitters

Honeywell’s SmartLine Multivariable Transmitters (SMV800) extend its proven smart technology to the simultaneous measurement of three separate process variables according to standard industry methods for air, gases, steam and liquids. They also offer the ability to calculate compensated mass or volume flow rate as a fourth process variable. In addition, meter body-only components are also available to support third party and OEM metering solutions.

SmartLine ST700 Pressure Transmitters

Honeywell’s SmartLine ® ST700 Pressure Transmitters include absolute pressure, gauge pressure, flange mount and remote seal transmitters that meet industry requirements in performance, stability, reliability and rangeability. With innovative modularity and an intuitive human machine interface (HMI), these products are ideal for a wide range of industrial process applications

You can also select and configure your SmartLine Pressure Transmitter using the Application and Validation Tool. Click on the box below to experience the tool

SmartLine ST800 Pressure Transmitters

Honeywell’s SmartLine® ST800 Pressure Transmitter family includes absolute pressure, gauge pressure, draft range pressure, flanged and remote seal transmitters. Refineries, chemical and pharmaceutical plants and paper mills around the globe rely on these transmitters for accurate and consistent pressure measurement.

Want to see how SmartLine ST800 Pressure Transmitters lead the industry in accuracy? Compare them with others in the market.

SmartLine Level Transmitters

With best-in-class performance, modular construction, an advanced display and the best integration features, SmartLine® Level Transmitters deliver total value across the entire plant lifecycle by helping users:

- Reduce engineering effort, project costs and startup time

- Avoid unplanned downtime and application errors

- Increase security against unauthorized access

- Reduce spare parts inventory

- Shorten time to repair.

Honeywell offers the SmartLine Level Application and Validation Tool that helps users determine the optimal measurement solution for their application.

SmartLine RM Series – Guided Level Meters

Honeywell’s SmartLine® Guided Radar Level Meters use TDR (Time Delay Reflectometry) to measure distance, level, interface, volume and mass. Higher signal dynamics and a sharper pulse than conventional TDR devices ensure better performance.

What Is It?

The SmartLine Guided Radar Level Meter can measure the level of a wide range of liquid products on a large variety of installations within the stated pressure and temperature range, including LPG and LNG. It can be deployed in blending tanks, distillation tanks, process tanks, separators, solid silos (inventory) and storage tanks. It does not require calibration or commissioning when installed, and can measure liquid interface with or without an air gap.

The level meter can also measure level and interface simultaneously as it has an optional second analog output. Lastly, the level meter can measure powders and granulates of materials with dielectric constants of 1.6 and even lower. A variety of rigid and flexible probes allow measurement in silos up to 35 m (115 ft) high.

SmartLine RM Series – Non-Contact Radar Level Meter

Honeywell’s SmartLine® Non-Contact Radar Level Meter measures distance, level, volume and mass. Based on FMCW (Frequency Modulated Continuous Wave) technology, it provides a more stable measurement than pulse radar and is well suited for agitated process conditions and the most demanding applications.

What Is It?

The SmartLine Non-Contact Radar Level Meter can measure the level of a wide range of liquid or granular products on a large variety of installations, including LPG and LNG. The level meter does not require calibration or commissioning when installed and can be applied in agitated process conditions and agitated vessels. The product is available in two versions; the RM70 has its electronics designed specifically for liquids, while the RM60 is meant for powders or granulates.